Zhejiang Four Brothers Rope Industry Co., Ltd

Zhejiang Four Brothers Rope Industry Co., Ltd. is located in Taizhou City, Zhejiang Toumen Port New area, the geographical position is superior, the company covers a total area of more than 56,000 square meters, construction area of 81,764 square meters, annual capacity of 35,000 tons, is the current domestic production capacity, equipment and technology leading full series of cable companies. The company can produce various specifications and chemical fiber made of 3mm-300mm diameter, a single length of 3000M large, ultra-long, super strong chemical fiber ROPE, long-term OEM production for Japan OBMA ROPE, most of the products exported to Europe and the United States market, chemical fiber rope single export amount of the industry leading, the company has more than 350 employees.

Being a member unit of the National aquatic Standardization Technical Committee, a member unit of the salvage professional Committee of the Chinese Society of Navigation and the Polar Navigation Equipment Committee, and has participated in the drafting and formulation of a number of national standards and industry standards. At the same time, the company is headquartered in London international shipowners purchasing organization IMPA and the international rope industry association CI member, participated in the discussion and formulation of many international rope standards, and Shanghai Maritime University to establish a “new materials, new technology, new applications” joint laboratory, has a corporate scholarship in the university of Shanghai. The R & D center of the enterprise is the “China Special Rope R & D Center” awarded by the China Textile Industry Federation.

Our mission is to help users achieve “cost control and security of the whole life cycle”, and has won wide recognition in the market. Successful key projects for the state and ministries include China deep-sea oil and gas exploitation project of CNOOC “Lingshui 17-2” project, “Deep-sea No. 1” platform, “Shenzhou” spacecraft return capsule Marine emergency rescue system, “300,000 tons tanker VLCC”, “400,000 tons ore carrier VLOC”, “24,000 container carrier”, “170,000 square LNG-FSR “U Transport ship”, “Snow Dragon 2” polar research ship and large ships, etc., provide chemical fiber rope supporting products and services, and won the praise of users.

Our Products

POWERHMPE®

Specific gravity:0.97g/cm³

Melting point:140℃

Elongation:2.8%

Water absorption:None

● Twisted with UHMWPE film (monofilament) fibers

● Low stretch and lightweight

● The second-strongest below common UHMWPE

● Outstanding wear resistance

● Excellent UV resistance and flex-fatigue

● Higher cost performance than common UHMWPE

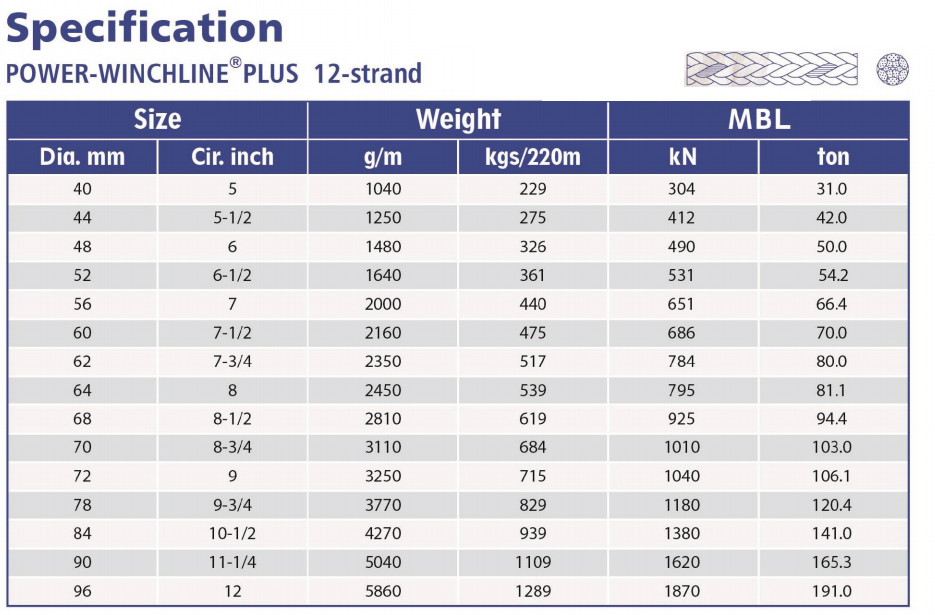

POWER-WINCHLINE®PLUS

-

Specific gravity:1.14g/cm³

-

Melting point:215℃

-

Elongation:14-25%

-

Water absorption:Yes

-

● Single braided with Nylon multifilament fibers & monofilament fibers

● Torque free

● High Elasticity

● Very good wear resistance

● Good resistance to chemicals

● Longer service life

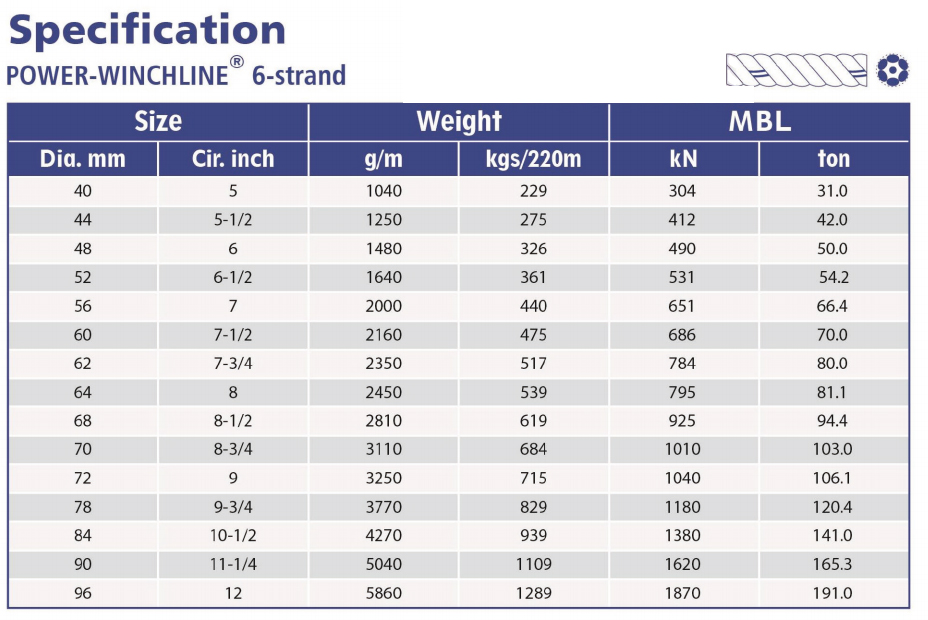

POWER-WINCHLINE®

-

-

Specific gravity:1.14g/cm³

-

Melting point:215℃

-

Elongation:14-25%

-

Water absorption:Yes

-

● Twisted with Nylon multifilament fibers & monofilament fibers

● High Elasticity

● Very good wear resistance in dry condition

● Good resistance to chemicals

● Longer service life

-

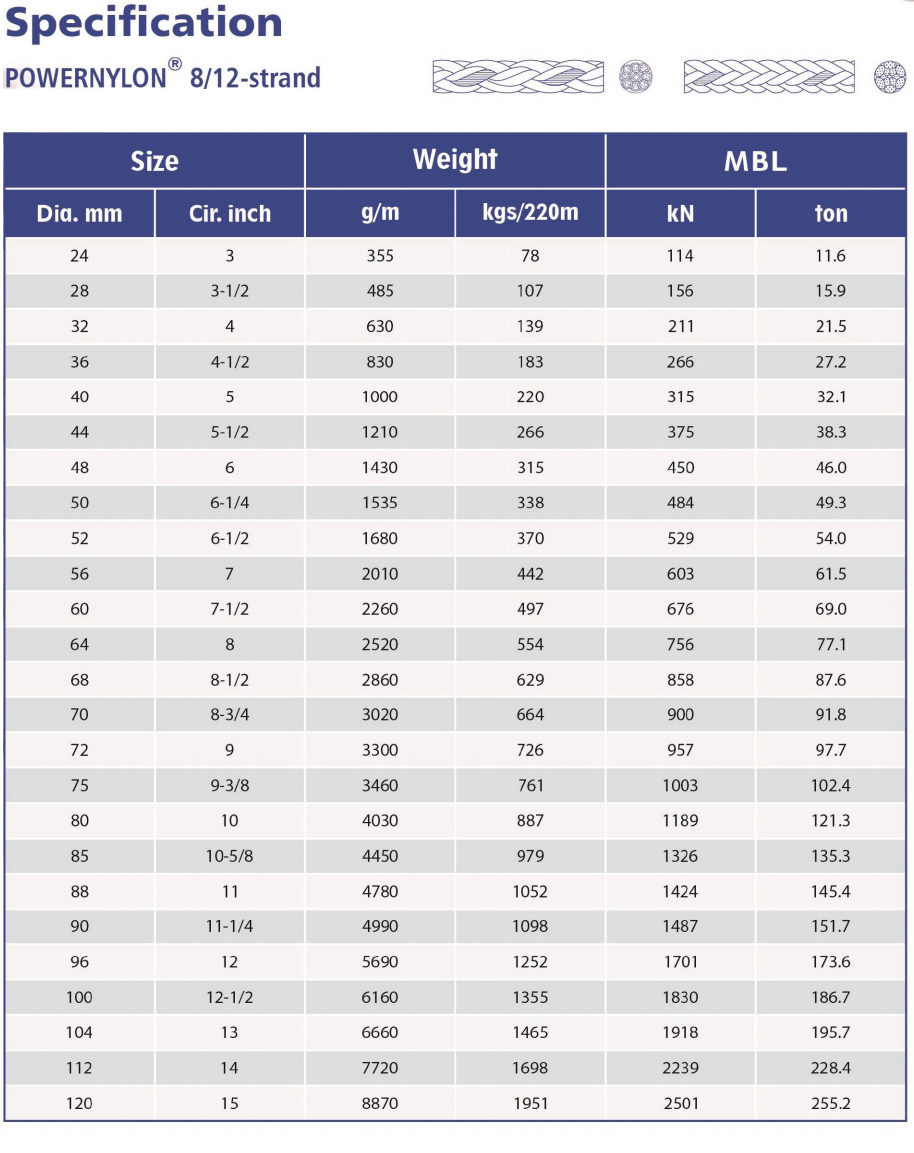

-

Specific gravity:1.14g/cm³

-

Melting point:215℃

-

Elongation:14-25%

-

Water absorption:Yes

-

● Plaited with Nylon multifilament fibers

● Torque free

● High elasticity

● Good UV resistance and good abrasion resistance

● Excellent shock absorption

● Good resistance to chemicals

● The breaking strength in wet condition is 10% to 15%lower than that of a new dry rope.

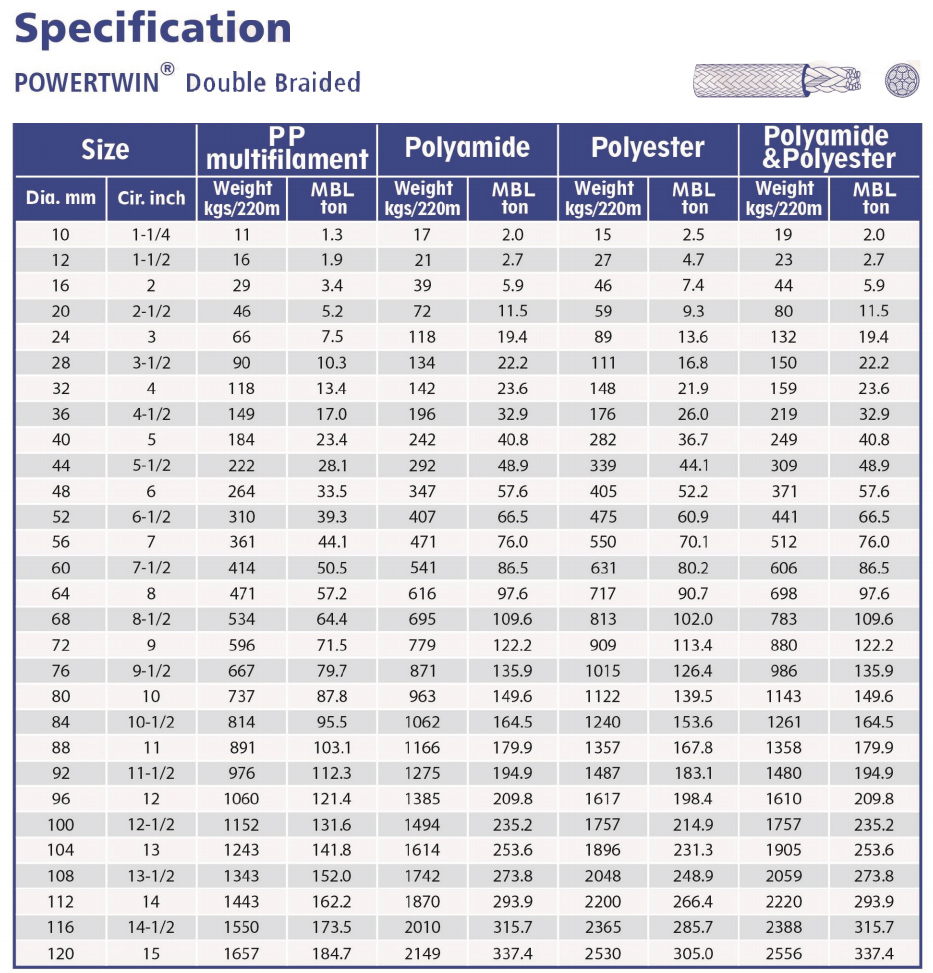

POWERTWIN®

● Double braided construction by different type of fibers

● Material covers PP multifilament, Polyamide, Polyester,Polyamide & polyester mixed

● Non-rotational and no kinking

● Good elasticity

● Good wear resistance

● Flexible and durable

-

Specific gravity:0.99g/cm³

-

Melting point:165/260℃

-

Elongation:12-17%

-

Water absorption:Yes

-

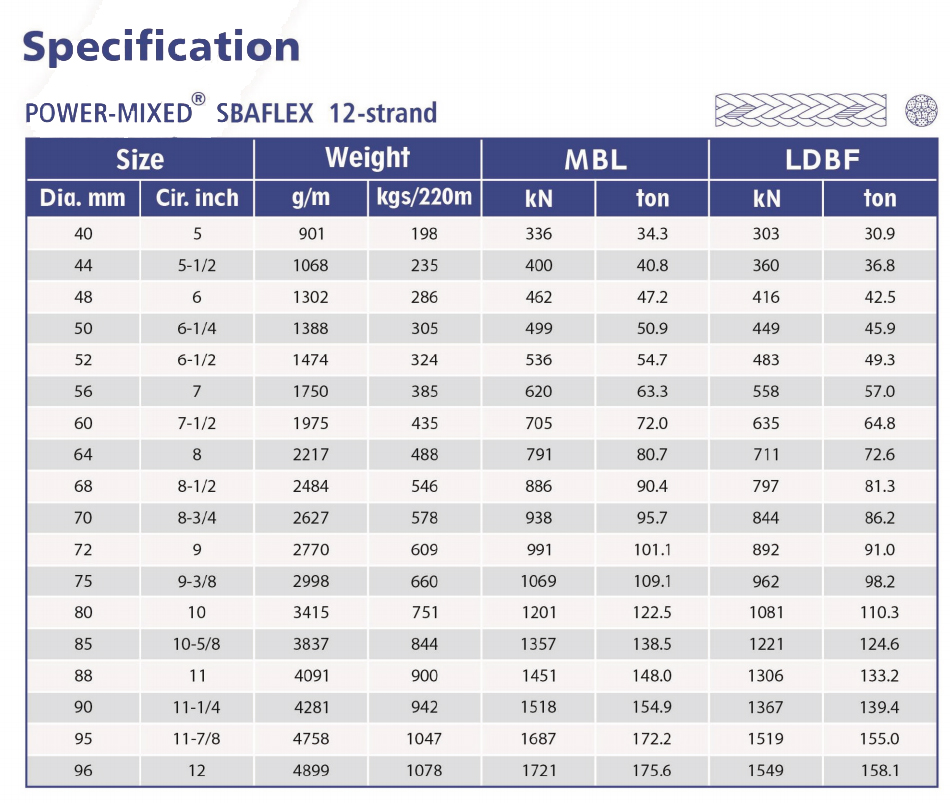

● Single braided construction made with blended high tenadity polyolefinand polyester fibers, combined with an inner-braid SBA part

● The surface of each strand are made with yarns that 100% polyesterfibers wrapping high tenacity polyolefin fibers

● Wet strength equals dry strength

● Torque free

● Good resistance to sunlight

● Good resistance to cyclic loading

● Very good grip

-

Specific gravity:0.97g/cm³

-

Melting point:140℃

-

Elongation:3.5%

-

Water absorption:None

-

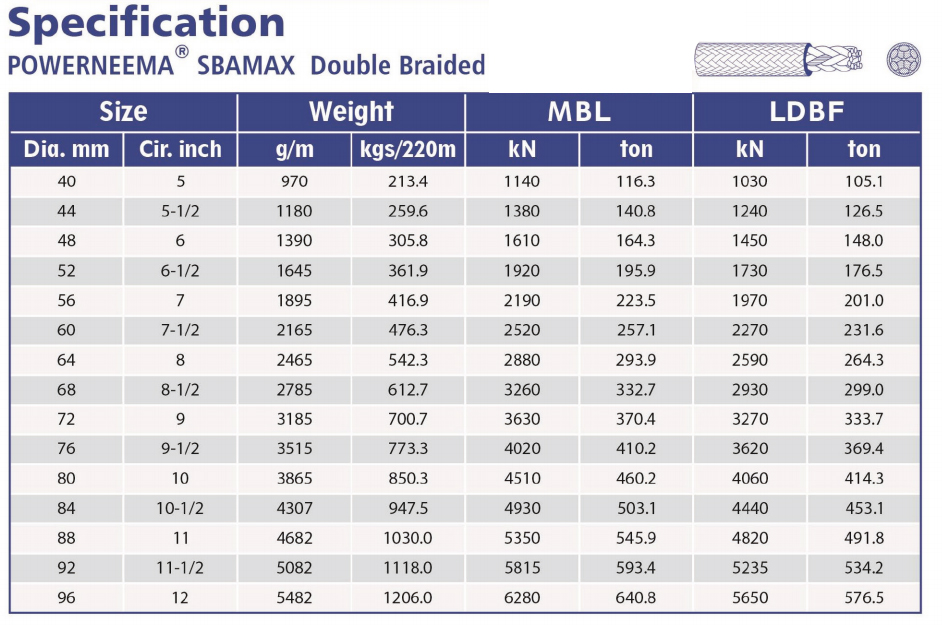

● Double braided construction made with UHMWPE fibers,combined with an inner-braid SBA part

● Non-rotational

● High strength-to weight ratio

● The tight UHMWPEjacket brings rope excellent wear resistance

● Excellent UV resistance

● Good grip

● Reduce recoil risk

-

Specific gravity:0.97g/cm³

-

Melting point:140℃

-

Elongation:3.5%

-

Water absorption:None

-

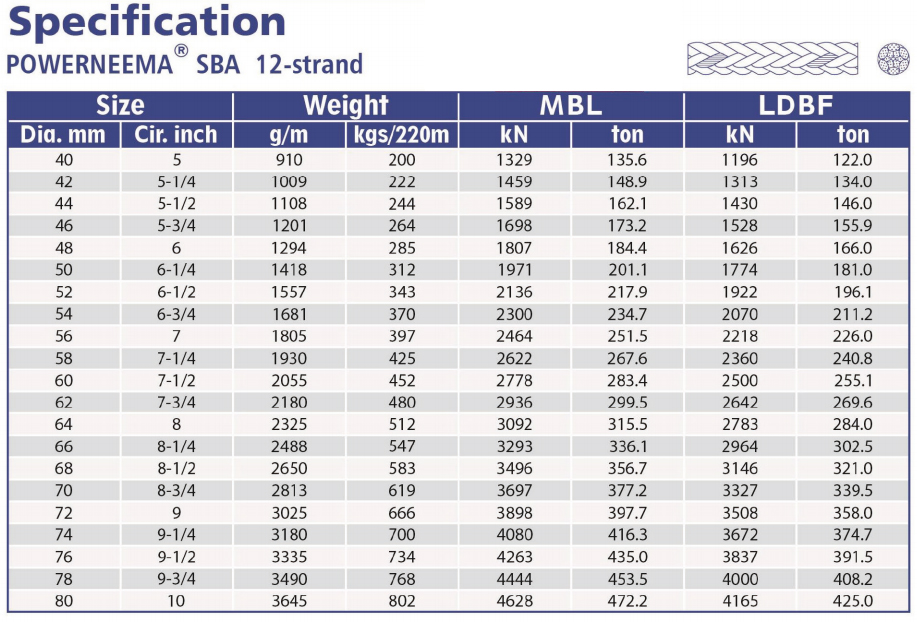

● Single braided construction made with UHMWPE fibers,combined with an inner-braid SBA part

● Torque free

● Lightweight and low stretch

● High strength-to weight ratio

● Excellent abrasion and UV resistance

● Superior resistance to chemicals

● Reduce recoil risk

-

Specific gravity:0.91g/cm³

-

Melting point:165℃

-

Elongation:16-20%

-

Water absorption:None

-

● Plaited by polypropylene multifilament fibers

● Also called “Floating Nylon”

● Wet strength equals dry strength

● Smooth and soft

● Easy handling

-

Specific gravity:0.92g/cm³

-

Melting point:165℃

-

Elongation:13-16%

-

Water absorption:None

-

● Made with high tenacity polyolefin fibers (70% PP and 30% PE)

● Stronger than conventional Polypropylene

● Better grip

● Flexible and durable

-

Specific gravity:0.97g/cm³

-

Melting point:140℃

-

Elongation:3.5%

-

Water absorption:None

-

● Each strand made with loose UHMWPE yarns covered by braided jacket

● Maximum strength-to-weight ratio

● Each covered strand brings excellent wear resistance to the rope

● Non-rotational

● Excellent resistance to sunlight & chemicals

● Flexible and easy handling

-

Specific gravity:0.92g/cm³

-

Melting point:165℃

-

Elongation:8-10%

-

Water absorption:None

-

● Plaited by high density polyolefin fibers

● Stretched and heat set under applied load

● Lower stretch

● Super stronger than conventional Polypropylene

● Flexible and durable

-

Specific gravity:Floating

-

Melting point:165/260℃

-

Elongation:12-17%

-

Water absorption:Yes

-

● 75% high density polyolefin and 25% polyester fibers blended with 100%polyester covering each strand’s surface.

● Wet strength equals to dry strength

● Higher strength than standard ropes

● Flexible and easy handling

● Economical

-

Specific gravity:Floating

-

Melting point:165/260℃

-

Elongation:12-17%

-

Water absorption:Yes

-

● 70% high density polyolefin and 30% polyester fibers blended

● Wet and dry strength are equal

● Lighter than 100% polyester ropes

● Good grip

● Flexible and easy handling

● Economical

-

Specific gravity:Non-floating

-

Melting point:165/260℃

-

Elongation:12-17%

-

Water absorption:Yes

-

● 50% high density Polyolefin and 50% polyester fibers blended

● Wet strength equals to dry strength

● Higher strength than conventional ropes

● Flexible and easy handling

● Economical

-

Specific gravity:1.0-1.1g/cm³

-

Melting point:140/260℃

-

Elongation:4-5%

-

Water absorption:Yes

-

● UHMWPE(core) and Polyester(Outer layer)

● High strength

● Torque free

● Protective jacket brings superior abrasion resistance and grip

● Excellent UV resistance

● Flexible and easy handling

-

Specific gravity:0.97g/cm³

-

Melting point:140℃

-

Elongation:3.5%

-

Water absorption:None

-

● UHMWPE(core) and UHMWPE(Outer layer)

● High strength and low stretch

● Torque free

● Protective jacket brings quite good abrasion resistance and grip

● Excellent resistance to sunlight and chemicals

● Flexible and easy handling

-

Specific gravity:0.97g/cm³

-

Melting point:140℃

-

Elongation:3.5%

-

Water absorption:None

-

● Plaited with UHMWPE fibers

● Extremely low stretch

● Equivalent strength to wire rope but 1/7 weight

● Maximum strength-to-weight ratio

● Non-rotational

● Excellent UV resistance and wear resistance

● Easy to handle and splice